Setting Up The Sys/resurrect

When you print file sys/resurrect.g it performs the following operations:

- Set bed and chamber heater temperatures

- Set all tools and heaters to their saved temperatures and other parameters, and set tools to active or standby as needed

- Call sys/resurrect-prologue.g

- Restore fan speeds, move the head to where it stopped printing, and resume the print

At the very least, your sys/resurrect-prologue.g file must do the following:

- Home the printer, without crashing the head into the print. On a delta, or on a Cartesian or CoreXY printer with a Z max homing switch, you can home all axes. On other types of printers you may have to skip homing Z and use a G92 command to tell the printer the current Z coordinate. If you choose not to home an axis, then even if the print head hasn’t moved since power down, the motor positions will change by up to 4 full steps compared to their position at power down. Note: recent firmware versions write a G92 command containing the coordinates at the time of failure into resurrect.g, just before the call to resurrect-prologue.g. So you may get away without homing axes. But it is still best to home any axes that you can .

- Execute M116 to wait for all heaters to reach operating temperature. You may do this either before or after homing axes.

- If your power fail procedure in the M911 command retracts filament and your printer has a single nozzle, you may wish to undo the retraction.

Example resurrect-prologue.g file for a delta printer:

What Happens When Prusa Runs Out Of Filament

after about 30 minutes, the extruder heater will shut down but the heatbed will retain its normal temperature if this has happened, you will have to wait for the extruder to reheat, after initiating the filament change process, dont go away, wait for the filament to unload, and continue as above!Feb 2, 2019.

Tape Down The 3d Print

Once the build plate has cooled down, the object has little to no adhesion to the build plate anymore. So if you’re not fortunate to catch the print shut off while the plate is still warm, we need to ensure the print job doesn’t move. Take a generous amount of tape and tape off the brim of your 3d print to the build plate.

Don’t Miss: How To Add Lines For Resume In Word

Guide: Resuming A Failed 3d Print

Just a quick PSA before we start. If youre currently reading this because this happened to you only minutes ago, make sure you go back to your printer and keep the bed heated so that your part doesnt release from it.

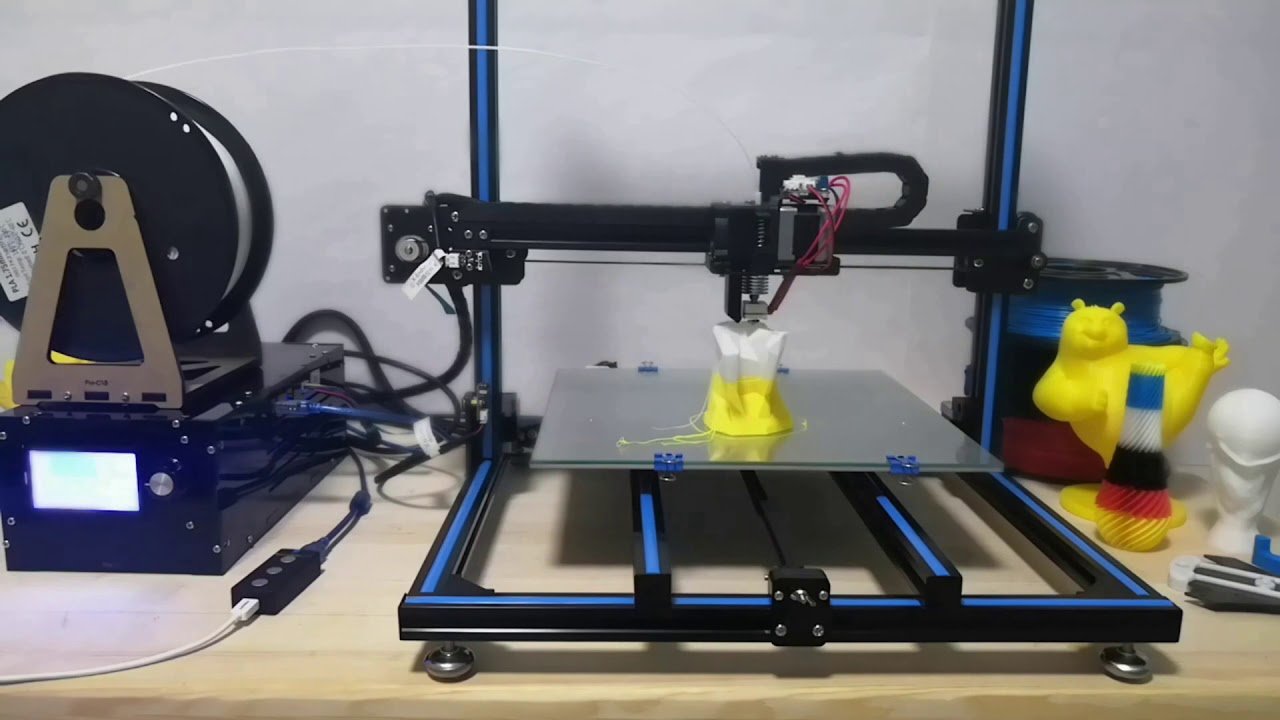

Im quite sure that almost anyone who owns a 3D printer already had a long print fail at some point just because no material somehow got extruded anymore. This is precisely what happened to me a bunch of weeks ago while filming my filament recycling video. I was easily able to continue mine with some simple G-Code trickery and thought this is actually an essential skill Id like to teach you. Maybe even make a print fail on purpose and try to recover it with these methods before this happens with a precious 3-day print! Let me know in the comments if you ever recovered a failed print and how you were able to do it! My print failed because I had a small piece of metal in my recycled filament that at some point blocked the nozzle. In your case, you could also run out of power, encounter heat creep, have a knot in your filament, or even run out of filament without a material sensor.

The highest priority is that you keep your print attached to the print bed, and if you have a removable print sheet, then also dont move it in any way because otherwise, we wont be able to resume the print at the correct location.

Can You Pause A 3d Print

The answer is yes you can pause a 3D print. The majority of the printers in the market today come with the Power-loss Recovery feature.

When you have this feature in your 3D printer and there is a power cut off, you can resume the print layer after a prompt when you turn the printer back on. Make sure that your SD card is initialized by the printer to get the option to resume the print.

However, one thing you should be keen about is that you have to ensure that the part remains attached to the plate. If it comes loose at any point, resuming the printing process becomes a challenge.

You could possibly try to use some kind of adhesive to get the model to stick to the bed again, but youd have to be very precise, mixed with a little luck!

Pausing your 3D prints is not something I would advise you do on a regular basis and avoiding it would be the best option if you can.

When you pause prints for a considerable amount of time, the printed model will shrink and may end up shrinking during the pause. ABS has a significant rate of shrinkage compared to PLA and PETG.

If you are using a glass bed, you might actually have your 3D print pop off the bed after cooling, so youd want to keep the bed temperature constant.

Thats not all upon resumption of the printing process, the bonds between the layers of the new and the old art may be weaker.

Recommended Reading: How Do I Update My Resume On Linkedin

Can You Melt Down Failed 3d Prints

Make reusing 3D printing waste into new pallets by turning your 3D printing waste into 3D printed filament.If the print fails, the recycler smashes it into smaller pieces, melts it down, and opens the container to let the liquid th failed prints into smaller pieces, melt them down, and force the liquid plastic through an opening.After the hot plastic has cooled down and coiled up, the reels are pulled.

Can Simplify3d Slicer Resume Printing After A Power Outage

Yes, you can resume printing by following the steps below:

- You must measure the distance from the objectâs base to the top of the last layer printed.

- In Simplify3D, you must change the height to Z.

- Then you must generate a new print G-Code and start the process of this second part.

- Once the second part is complete, you must sand and glue both pieces to obtain your final model.

- You can clean the edges and remove the glue residues to an excellent finish when the object is ready. However, you will not notice all these details if you intend to paint the object.

You May Like: How To List Wpm On Resume

Convert Height To Number Of Layers

Now, since I trust that none of you actually counted the individual layers, we’re just going to employ a neat technique to find the number of layers. Back to junior high math class:

“The printed height is 35mm. The height of each layer is 0.15mm per layer. How many layers are printed?”

You can find the height of each layer in the print setting you have for the gcode. By default the unit is mm per layer.

Quick Steps To Restart The Printer In Octoprint

- Go to G-Code Scripts and press the configuration button or wrench.

- Enter the specific command for print pause cases in the section âafter print job is pausedâ .

- Then you should do the same in the âBefore print job is resumed section.â You can also use M82 depending on whether you are using Cura or Simplify3D or M83 if you are using another slicer program. The conclusion is that it all depends on how each slicer program generates the G-Code.

Don’t Miss: How To List Summa Cum Laude On Resume

Dont Remove The Model

If your 3D model is still on the printer bed, follow the steps below:

Clean the Last Layer That Was Printed

Very gently, you should clean the last layer printed before the power is cut off. Remove the imperfections on the unfinished model, and that includes clearing out the leftover material.

You should also be on the lookout for those areas that werent printed properly. Remove the dried threads of filament and even support materials.

Measure the Height Where the Printing Failed

Here are several ways that you can get an accurate height on your failed models:

- Using calipers or a ruler, you can measure the height of the failed print from the base.

- Look at the geometrical features. Open the G-code for your model and look at the geometrical features and sections where the print failed.

- Use your 3D printer. You can also move your 3D printers nozzle so that it touches the last layer printed. Look at the height on your 3D printers screen.

After you get the height where the printing failed, its time for you to figure out at which point youd want your 3D printer to resume printing. There are two schools of thought on this.

Modify the G-Code

Removing the half-printed part from the heated bed, you can measure it from the base. Taking note of those measurements, youll need to edit the G-code for that particular model to start at the point where the printing process was interrupted.

Resume the Print

What To Do if the Z-Axis Cant Be Homed

Can 3d Prints Be Recycled

ABS and PLA are not recyclable under most curbside waste recycling programs because they are two of the most common 3D printer filament types.Type 7, or Other Resins were added to ASTM International Resin Identifier Codes earlier this year, which are not commonly processed by local wastewater treatment facilities.

Read Also: How To Add A Line In Word Resume

How To Pause & Resume 3d Prints With Octoprint

Say you are using your OctoPrint, and you realize you have to attend to something urgent during the process what do you do? Is it possible for you to pause and resume your 3D prints successfully with OctoPrint?

There is a simple pause function within OctoPrint which will stop a current 3D print, but resuming the print takes some extra commands since the nozzle wont automatically be in the ideal position.

If you are pausing to change your filament, its important to move the print head away from the model since the nozzle will stay pause where it was.

To successfully resume your printing from a paused 3D print in OctoPrint, you need to go into G-Code Scripts which youll find by clicking the wrench symbol.

Now look at the After print job is paused section and enter the following:

relative XYZE

move back to pause position XYZG1 X} Y} Z} F4500

reset to feed rate before pause if availableG1 F}

If you are using Cura or Simplify3D, you can successfully use M82 in the Before print is resumed section, but if you are using another slicer like Slic3r, you may have to use M83 instead. This depends on how G-Code is generated within the slicer.

One user found better luck by setting the park position of the extruder to something like 5,5 rather than 0,0. It works better if you rely on mechanical endstops because there is a slight variation on triggering.

Multiple Ways Of Recovering A Failed Print

Its a special gut-dropping, grumbly moment that most who use 3d printers know all too well. When you check on your 13-hour print, only to see that it failed printing several hundred layers ago. from has a few clever tricks to resume failed prints.

It starts when you discover your print has failed and whether the part is still attached to the bed. If it has detached, the best you can do is whip out your calipers to get a reasonably accurate measurement of how much has been printed. Then slice off the already printed section, print the remainder, and glue the two parts together. If your part is attached to your print bed and you havent shifted the plate , start by removing any blemishes on the top layer. That will make it smooth and predictable as its starting a new print, just on top of an existing one. Measuring the height that has been printed is tricky since you cannot remove it. Calipers of sufficient length can use their depth function, but you might also be able to do a visual inspection if the geometry is unique enough. After you load up your model in a G-Code viewer, go through it layer by layer until you find what matches what has already been printed.

If all the doesnt work, and the print is still unrecoverable, perhaps you can look into recycling the plastic into new filament.

Recommended Reading: No Prior Work Experience Resume

How Can I Fix My 3d Printer

Acetone Clean the surface of both 3D printed parts with sandpaper to flatten the surface. Apply a thin layer of acetone to both surfaces with a brush or a cloth. Now connect the two pieces with a clamp or even some tape and let it sit. After drying out, your pieces should be nicely bonded back together.

What Happens When A 3d Print Fails

In mid print, a layer may fail to stick together properly when the geometry has been changed, based on the models geometry.Maybe youre printing too slowly at a temperature thats too low on the printer.To ensure the layers are truly fuseable, increase the print temperature from a moderate setting to a higher one.

Don’t Miss: Work History Example

Slicing Your Prints Manually

First, let’s verify that the layer height is indeed at 233 layers when it stopped. Open your slicer, mine is Cura and switch to layer view and view everything up to the 233th layer. If it looks the same as what you have physically then it’s probably right or around that height. It’s hard to tell precisely since you’re only getting a resolution to 1mm which is around 7 layers.

Then open the gcode in a text editor. Don’t use notepad. I use sublime text since I have it around for coding. You can also use notepad++. Delete the lines in between layer:0 and layer:233. It’s a huge file so it might take a while to traverse. Save the new file with a new file name just in case we overshoot and want some old deleted layers printed.

Then as a final sanity check, open up the new gcode in your slicer and view the free floating print

Tips On How To Resume A 3d Print Job After Turning Off The Printer

Due to the amount of time it costs to design a 3D model and then 3D print it, we ideally want to be in a situation where we can start a 3D printer when we need to and turn it off when the print job is done. But lets face it. We arent always in the situation where a 3D print job can be completed before having to stop the job, turn off the 3D printer, and even move the print but interruptions dont have to be the end of the world. Using a MakerGear M2 3D printer and the 3D printing slicing software Simplify3D, Vicky Somma was able to remove an in-process print job, pack it up, take it home and restart it exactly where it had left off.

Somma, an enthusiastic, self-taught 3D designer and maker whose work we have admired before, writes a blog dedicated to all things 3D, and her latest entry details how she restarted a print job that had to be stopped and moved partway through. After stopping a display print and unplugging her machine at the , once Somma returned home, there were a few essential steps she had to take to be able to resume her print job again:

Before I could resume printing, I needed to rehome all my axises so my nozzle had all its bearings, particularly the tricky Z axis. In this case, my print was not very high, so under the Machine Control Panel in Simplify3D, I was able to move the bed around to a good spot for me to hit Home Z without my print hitting the nozzle or the X axis support bar.

Recommended Reading: Resume Rewording Tool

Can I Pause My 3d Printer Overnight

Print can sometimes be paused for several hours overnight.The pause feature is included in most 3D printers.The control box of your 3D printer or your slicer file instructions will probably give you the option of preventing a 3D print.It is however important to remember that pausing the print throughout the night may cause some problems.

How Do I Continue A Failed 3d Printer

Step 1: Stay Clear! move your nozzle clear of the print. Step 2: Fix You Extruder. if your extruder is clogged fix it now. Step 3: Find Z Height. carefully find the height your print failed at. Step 4: Fix G Code. Step 5: Upload G Code. Step 6: Prime Your Extruder. Step 7: Hit Print! Step 8: Enjoy.More items

You May Like: When To Include Gpa On Resume

How To Continue A Stopped 3d Print

3D printers are the staple for quick and cheap prototyping nowadays. I am one of those fortunate enough to own a 3D printer, courtesy of an Instructables contest.

There are still a lot of improvements to be made with 3d printing technology. One such improvement is having non-volatile memory such that a 3d printing job can be resumed after it is accidentally turned off or if the SD card is accidentally removed.

Whether it is caused by a sudden power outage or a rude roommate, we would always have to restart a 3d print from scratch and this is especially annoying for long or difficult prints.